Small Diameter Furnace Graphite Electrode bakeng sa sebōpi sa motlakase sa arc bakeng sa indasteri ea tšepe le ea motheo.

Tekheniki Parameter

Chate 1: Technical Parameter For Small Diameter Graphite Electrode

| Diameter | Karolo | Khanyetso | Flexural Matla | Modulus e monyane | Botenya | CTE | Molora | |

| Intshi | mm | μΩ·m | MPa | GPA | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1,64 | ≤2.4 | ≤0.3 |

| Nnyo | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1,64 | ≤2.4 | ≤0.3 |

| Nnyo | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1,63 | ≤2.4 | ≤0.3 |

| Nnyo | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1,63 | ≤2.4 | ≤0.3 |

| Nnyo | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1,63 | ≤2.4 | ≤0.3 |

| Nnyo | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1,63 | ≤2.4 | ≤0.3 |

| Nnyo | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Chate ea 2: Bokhoni ba ho Jara ba Hona Joale Bakeng sa Electrode ea Graphite ea Diamethara e Nyenyane

| Diameter | Moroalo oa Hona Joale | Boima ba Hona Joale | Diameter | Moroalo oa Hona Joale | Boima ba Hona Joale | ||

| Intshi | mm | A | A/m2 | Intshi | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Chate ea 3: Boholo le Mamello ea Graphite Electrode bakeng sa Diamethara e Nyane ea Graphite Electrode

| Nominal Diameter | Bophara ba 'Nete(mm) | Bolelele ba Lebitso | Mamello | |||

| Intshi | mm | Max. | Min. | mm | Intshi | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75 ~ +50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75 ~ +50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ±100 |

Kopo e ka Sehloohong

- Ho qhibiliha ha calcium carbide

- Tlhahiso ea carborund

- Ho hloekisa Corundum

- Litšepe tse sa tloaelehang tse qhibilihang

- Ferrosilicon semela refractory

Litaelo Ho fana le ho Sebelisa Bakeng sa Li-electrode tsa Graphite

1.Tlosa sekoahelo se sireletsang sa lesoba le lecha la electrode, hlahloba hore na khoele e ka har'a sekoti sa electrode e phethehile 'me khoele e sa phethoa, ikopanye le baenjiniere ba litsebi ho fumana hore na electrode e ka sebelisoa;

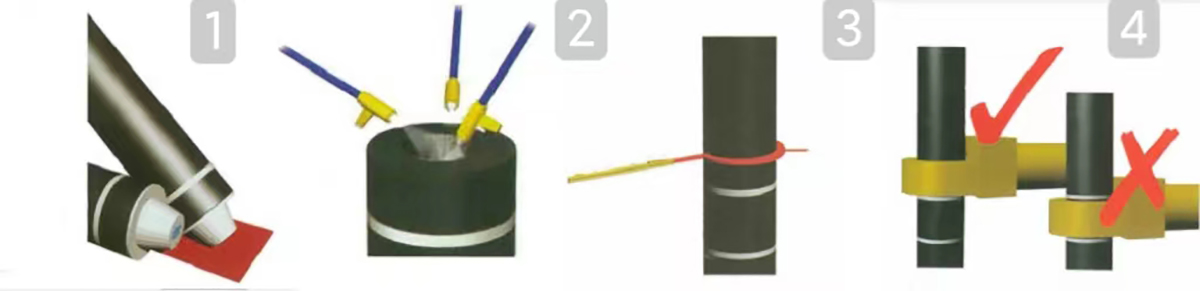

2. Khutlela hanger ea eleketrode ka lesobeng la eleketrode ka lehlakoreng le leng, 'me u behe mosamo o bonolo tlas'a ntlha e 'ngoe ea eleketrode ho qoba ho senya lenonyeletso la eleketrode;(sheba pic1)

3.Sebelisa moea o hatelitsoeng ho phethola lerōle le li-sundries holim'a metsi le lesoba la electrode e kopanyang, ebe u hloekisa bokaholimo le sehokelo sa eleketrode e ncha, e hloekise ka borashe;(sheba pic2)

4.Phahamisa electrode e ncha ka holim'a electrode e emetseng ho ikamahanya le lesoba la electrode le ho oa butle;

5.Sebelisa boleng bo nepahetseng ba torque ho notlela electrode hantle;(sheba pic3)

6.Sets'oants'o sa clamp se lokela ho behoa kantle ho mohala oa alamo.(sheba pic4)

7.Nakong ea ho hloekisa, ho bonolo ho etsa hore electrode e tšesaane ebe e baka ho robeha, ho oela ha motsoako, ho eketsa tšebeliso ea li-electrode, ka kopo u se ke ua sebelisa li-electrode ho phahamisa carbon content.

8.Ka lebaka la lisebelisoa tse sa tšoaneng tse sebelisoang ke moetsi e mong le e mong le mokhoa oa ho etsa lihlahisoa, thepa ea 'mele le ea lik'hemik'hale ea li-electrode le manonyeletso a moetsi ka mong. Kahoo ha e sebelisoa, tlas'a maemo a akaretsang, Ka kopo u se ke ua kopanya li-electrode le manonyeletso a hlahisoang ke bahlahisi ba fapaneng.