UHP 450mm Furnace Graphite Electrodes With Nipples T4L T4N 4TPI

Tekheniki Parameter

| Paramethara | Karolo | Yuniti | Lintlha tsa UHP 450mm(18”). |

| Nominal Diameter | Electrode | mm(inch) | 450(18) |

| Max Diameter | mm | 460 | |

| Min Diameter | mm | 454 | |

| Bolelele ba Lebitso | mm | 1800/2400 | |

| Max Length | mm | 1900/2500 | |

| Min Length | mm | 1700/2300 | |

| Max Current Density | KA/cm2 | 19-27 | |

| Bokhoni ba ho Jara ba Hona Joale | A | 32000-45000 | |

| Khanyetso e Itseng | Electrode | μΩm | 4.8-5.8 |

| Nnyo | 3.4-3.8 | ||

| Flexural Matla | Electrode | Mpa | ≥12.0 |

| Nnyo | ≥22.0 | ||

| Modulus ea Bacha | Electrode | GPA | ≤13.0 |

| Nnyo | ≤18.0 | ||

| Boima ba Bongata | Electrode | g/cm3 | 1.68-1,72 |

| Nnyo | 1.78-1,84 | ||

| CTE | Electrode | ×10-6/℃ | ≤1.2 |

| Nnyo | ≤1.0 | ||

| Litaba tsa molora | Electrode | % | ≤0.2 |

| Nnyo | ≤0.2 |

TLHOKOMELISO: Tlhokahalo efe kapa efe e ikhethileng mabapi le dimension e ka fanoa.

Lisebelisoa

Li-electrode tsa graphite tse matla haholo (UHP) li sebelisoa lits'ebetsong tsa Electric Arc Furnace tse hlahisang tšepe ea boleng bo holimo le litšepe tse ling.Hape li sebelisoa haholo liindastering tse fapaneng, ho kenyeletsoa matla a nyutlelie, metallurgy, lik'hemik'hale, le tse ling.The UHP Graphite Electrode e boetse e tsejoa ka matla a eona a phahameng a mochini le ho nepahala ha mochini.Sena se tiisa hore li-electrode tsa graphite li matla ka ho lekaneng ho mamella matla a matla le likhatello tse ka hare ho sebōpi, ha li ntse li boloka sebōpeho le boholo ba tsona.Gufan e ikemiselitse ho hlahisa mefuta e mengata ea li-electrode tsa graphite tsa UHP ho fihlela tlhokahalo ea ts'ebetso e phahameng ea mosebetsi le litšenyehelo tse tlase bakeng sa bareki bohle ba lefats'e.

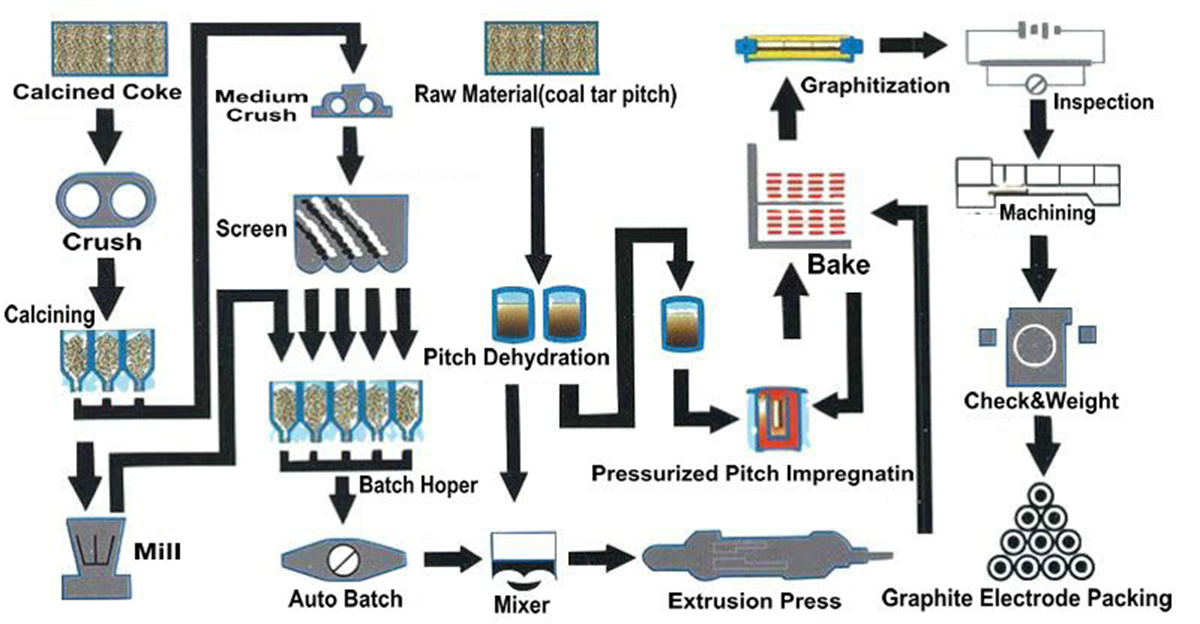

Chate ea Ts'ebetso ea Tlhahiso

Re romelle lengolo-tsoibila la lipotso, re tla ikopanya le uena ha re fumana lengolo-tsoibila la hau, kapa ikopanye le nna ka app ea moqoqo.

E, re etsa joalo.Letšoao la thomello le ka raloa le ho hatisoa joalo ka tlhoko ea hau.

Hangata nako ea ho fana ke matsatsi a 10 ho isa ho a 15 ka mor'a ho lefa kapa ho saena konteraka.Kapa nako ea ho fana e ka buisanoa haeba u hloka ho fana ka khoeli le khoeli kapa nako e 'ngoe e khethehileng.