Nyenyane Diameter Graphite Electrodes Rod Bakeng sa Motlakase Arc Sebōpi Ka tšepe le Foundry Indasteri

Tekheniki Parameter

Chate 1: Technical Parameter For Small Diameter Graphite Electrode

| Diameter | Karolo | Khanyetso | Flexural Matla | Modulus e monyane | Botenya | CTE | Molora | |

| Intshi | mm | μΩ·m | MPa | GPA | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1,64 | ≤2.4 | ≤0.3 |

| Nnyo | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1,64 | ≤2.4 | ≤0.3 |

| Nnyo | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1,63 | ≤2.4 | ≤0.3 |

| Nnyo | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1,63 | ≤2.4 | ≤0.3 |

| Nnyo | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1,63 | ≤2.4 | ≤0.3 |

| Nnyo | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1,63 | ≤2.4 | ≤0.3 |

| Nnyo | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Chate ea 2: Bokhoni ba ho Jara ba Hona Joale Bakeng sa Electrode ea Graphite ea Diamethara e Nyenyane

| Diameter | Moroalo oa Hona Joale | Boima ba Hona Joale | Diameter | Moroalo oa Hona Joale | Boima ba Hona Joale | ||

| Intshi | mm | A | A/m2 | Intshi | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Melemo

1.Kalafo ea anti-oxidation bakeng sa bophelo bo bolelele.

2.Bohloeki bo phahameng, boima bo phahameng, botsitso bo matla ba lik'hemik'hale.

3.High machining ho nepahala, molemo holim'a ho qeta.

4.Matla a phahameng a mechine, ho hanyetsa motlakase ho tlaase.

5.E hanana le ho petsoha & spalling.

6.Ho hanyetsa ka matla ho oxidation le mocheso oa mocheso.

Kopo e ka Sehloohong

- Ho qhibiliha ha calcium carbide

- Tlhahiso ea carborund

- Ho hloekisa Corundum

- Litšepe tse sa tloaelehang tse qhibilihang

- Ferrosilicon semela refractory

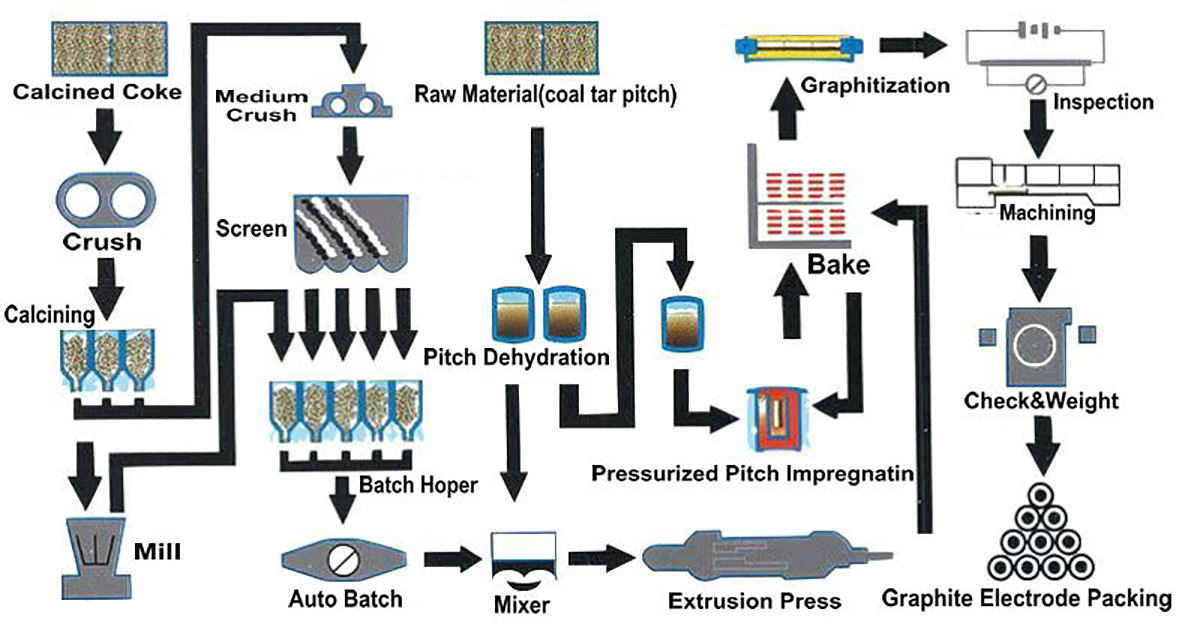

RP Graphite Electrode Production Process

Molaoli oa Boleng ba Bokaholimo

1.The mefokolo kapa masoba ha ea lokela ho feta likarolo tse peli holim'a graphite eleketrode holim'a, 'me mefokolo kapa masoba boholo se ke ua lumelloa ho feta ya data ho tafoleng e boletsoeng ka tlaase.

2.Ha ho na lepetso le pharollang holim'a holim'a electrode. Bakeng sa ho phatloha ha longitudinal, bolelele ba eona ha boa lokela ho ba ho feta 5% ea sedikadikwe sa electrode ea graphite, bophara ba eona bo lokela ho ba ka har'a mefuta e fapaneng ea 0.3-1.0mm. Longitudinal crack data tlas'a 0.3mm data e lokela ho ba. ba nyatsehe

3.Bophara ba sebaka se seholo (botšo) holim'a elektrode ea graphite ha ea lokela ho ba ka tlase ho 1/10 ea circumference ea electrode ea graphite, le bolelele ba sebaka se makukuno (botšo) ho feta 1/3 ea bolelele ba graphite electrode. ha e dumelle.